Check out our Double Knit Face Coverings!

-

Made from our soft and satiny 200 thread count 100% cotton sateen

-

Available in 3 youth and 4 adult sizes to suit a variety of face shapes

-

Internal pocket to accommodate a filter of your choice

-

Stainless steel adjustable nose piece and soft fabric ear ties

-

Printed with permanent reactive inks that won’t washout or fade away

Cotton Sateen Face Coverings are drop ship friendly!

Art of Where drop shipping and fulfillment services are a quality-centric way to create, expand, or enhance your artwork-based business! Print your artwork on our unique handmade product range and benefit from:

- No upfront costs

- Realistic mockups for your product listings

- Quick production times

- Seamless integrations with e-commerce platforms: Shopify, Etsy, WooCommerce, BigCommerce, Big Cartel, Squarespace

- Branded labels and packaging

Information

PROFIT CALCULATOR

| Size | Drop ship | Retail price | You make |

|---|---|---|---|

| Face Covering | $ | $ | $ |

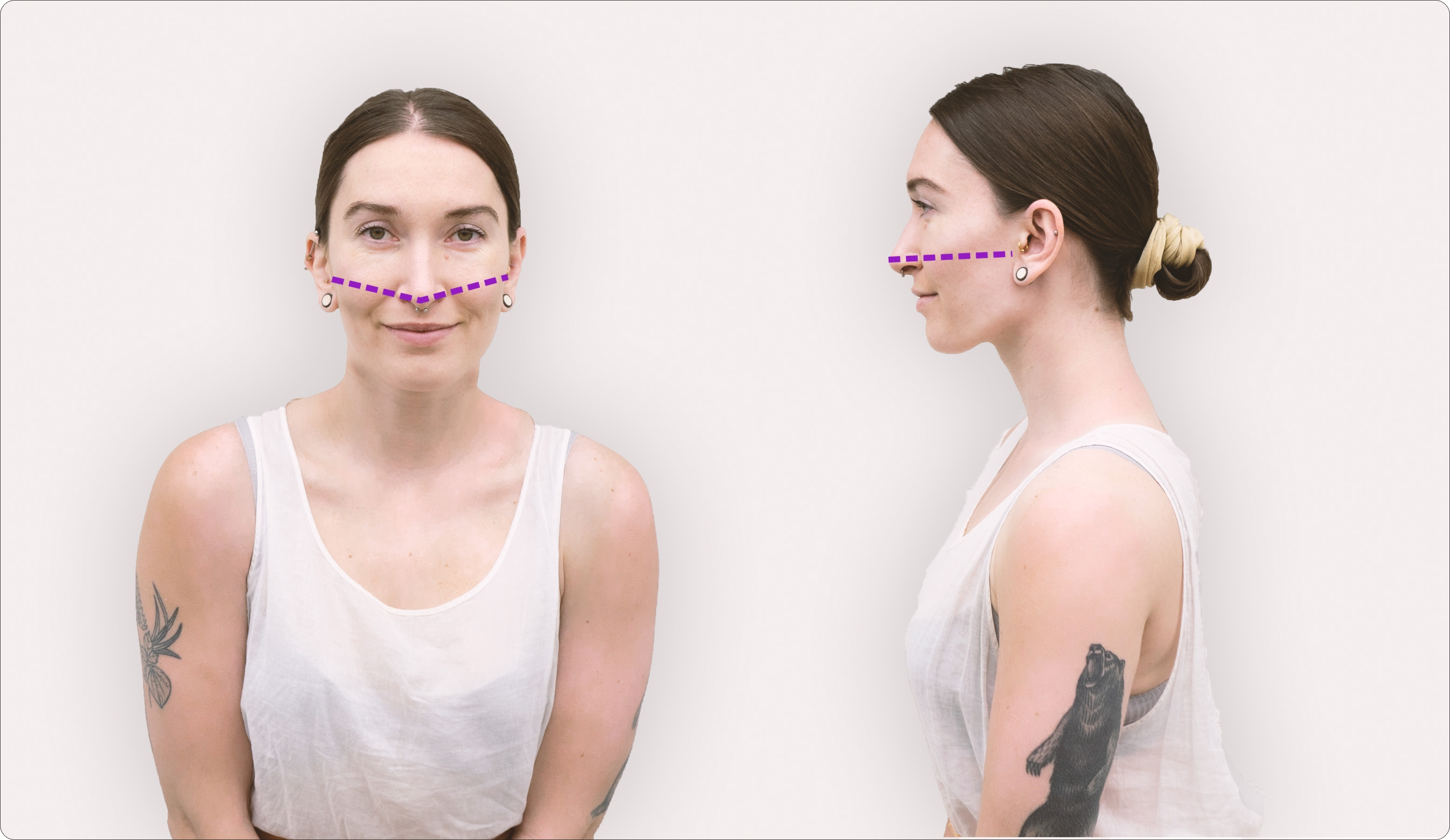

It’s important that your face covering fits as snug as possible to your face. Take some time to do the following measurements before you order. Don’t assume that your face size is similar to your clothing size! Face shapes can vary significantly from person to person.

• Measure from the beginning of one ear, over the tip of your nose, to the start of your other ear.

| Size | Ear-to-ear over nose |

|---|---|

| Adult X-Large | 30.5 cm |

| Adult Large | 29 cm |

| Adult Medium | 27.5 cm |

| Adult Small | 26 cm |

| Youth Large | 25 cm |

| Youth Medium | 23.5 cm |

| Youth Small | 22 cm |

Sticker

Artist Card

Brand your face covering with a custom artist card, and sticker.

| Product | Size in pixels | Size in inches | DPI |

|---|---|---|---|

| Face Covering | Front: 1998px x 1102px Back: 1108px x 1107px |

Front: 13.3" x 7.3" Back: 7.4" x 7.4" |

150 |

Important Information on Cloth Face Coverings

It’s important to have realistic expectations of cloth face coverings. Please refer to the resources below from government and health organizations to understand the implication of wearing and not wearing cloth face coverings.

From CDC.govWorld Health Organization

Government of Canada

FDA

How it's printed

Reactive Printing

Reactive printing is a multistep process formulated for printing on natural fabrics. It involves 4 main steps: pretreating fabrics, printing, steaming and washing.

The pretreatment process involves coating fabrics in a finely tuned chemical mixture that stiffens the fabric and helps bond the ink to the fabric. Once coated, the fabrics are digitally printed with reactive inks using color profiles suited to each fabric. It’s quick and insanely accurate! The CMYK ink set translates your artwork into millions of tiny drops that are jetted out from the technologically advanced print heads. After printing, steaming is where the magic happens! The fabric slowly moves through a steam chamber heated to 102 degrees Celsius which opens the fiber’s cells. Once opened, the ink can transfer into the fibers. After steaming the print will be at maximum vibrancy and color depth. The last step is washing to remove all excess inks and residual pretreatment. The fabric passes through 3 different temperature baths and we add special detergents and finishers to wash and significantly soften the fabrics.

It’s a long process but it’s worth it! All fabrics printed with a reactive process are fully washable with no fading and perfectly soft and ready to use for any project.

Reactive vs. Pigment

Unlike the reactive process detailed above, pigment printing is a short cut for natural fabric printing. It results in surface prints on natural fabrics where the inks do not penetrate into the fibers. While it is a fast process, pigment inks are not wash-fast and will fade with washing and rubbing. The colors produced in pigment printing are generally subdued since pigment inks are composed of not only the nanopigments (colors) and water, but also a glue to adhere the ink to the fabric surface. The glue also means your fabric feels stiffer after printing with no hope of softening without washing and color-loss. In contrast, reactive printing includes all the 4 steps detailed above and the end product is fully washed and ready for any end use. Reactive printing on natural fabrics means there’s never any compromise between colors, feel, finish, or wash fastness.

Environment Impact of Reactive On-demand Printing

Reactive printing on-demand is a low waste process. Since every meter we print is for a specific customer, we never have overstock or deadstock. Fabrics that we pretreat incorrectly can simply be washed and retreated. Our washing machinery recirculates water to minimize water usage. The steamer uses less than 40 liters of water most production days. We use natural gas heaters to power the printer heater and practice widely accepted energy saving techniques daily within our facility including recycling all cardboard, papers, and plastics.

Descriptions for your product listings

Sometimes it seems like there are a hundred little steps to go through when creating a product listing! To help make it a little bit easier for you, we’ve put together some listing descriptions that you can choose from and use for any purpose. Copy and paste as many times are you need!

General

We’re all trying to go the extra mile right now to stay safe and sanitary in the face of the global COVID-19 pandemic. Part of that is covering our faces in public. My 200 thread count cotton sateen face coverings are silky soft against your skin and printed with permanent reactive inks so they won’t fade even after endless washes. They feature a stainless steel nose piece to ensure a tight fit, and soft fabric elastic that can be adjusted to fit your head shape. They have an internal filter pocket which acts as the double layer of fabric while also allowing you to insert an additional filter suited to your needs. While we don’t have a choice to change our lifestyles to suit the world, we do get to choose the artwork that we wear! Cover up with custom printed face coverings and stay safe and stylish!

Compliance and Safety

Our cotton sateen fabric is made in a factory with OEKO-TEX Certification for standardized and safe working conditions. You can download the OEKO-TEX certificate to use in your product listings. All finishing chemicals used in our reactive print process are Blue Sign and GOTS certified.

Download original certificate

Download english certificate